A brief discussion on the design and application of wireless temperature measurement system in high-voltage switchgear

- Acrel

- Sep 25, 2024

- Events

Abstract: The high-voltage switchgear is an important electrical equipment in the substation. It is responsible for the dual functions of closing and disconnecting power lines and protecting the safety of the system. The high-voltage switchgear operates in an environment of high voltage, large current, and strong magnetic field for a long time. Oxidation and contact resistance often cause the contacts to heat up and the temperature is too high. If not discovered and dealt with in time, it may cause serious accidents such as fires, power outages, etc. Therefore, the problem of real-time temperature monitoring in high-voltage switch cabinets has become an urgent problem to be solved in the power system. The article on practical issues proposes a wireless temperature measurement system for high-voltage switch cabinets based on a single-chip microcomputer. The system has the characteristics of simple structure, temperature measurement, and high accuracy.

Keywords: high-voltage switchgear; wireless temperature measurement system

0 Introduction

With the rapid development of the people's economy, the demand for electric energy from all walks of life is getting higher and higher. Therefore, the safe and reliable operation of power equipment is an important part of the security of the power grid. High-voltage switchgear is one of the important equipment in the substation. Most high-voltage switchgear adopts a closed structure and has poor heat dissipation conditions. When the equipment is in operation for a long time, the contacts in the switchgear are prone to heat, causing components to age and cause fires. Accident Therefore, the internal overheating phenomenon of closed-structure high-voltage switch cabinets has become a common problem in switch cabinets.

1 Method for detecting internal contact temperature of high-voltage switchgear

At present, the heating conditions of the contacts inside the high-voltage switchgear are monitored, and the temperature changes can be grasped at any time, so that they can be handled promptly before they reach dangerous temperatures, so as to avoid safety accidents. Currently, the commonly used detection methods mainly include T inspection, color chip temperature measurement, optical fiber temperature measurement and infrared temperature measurement. Human inspection mainly relies on the operator's hand-held red-N thermometer to measure the temperature inside the high-voltage switch cabinet. However, due to the closed structure of the high-voltage switch cabinet and the obstruction of the circuits or components in the cabinet, the temperature inside the switch cabinet is blocked. As a result, the infrared thermometer cannot accurately measure the temperature data inside the cabinet. The color chip temperature measurement method is based on the different colors of the color chip to determine the temperature inside the cabinet. This method cannot accurately reflect the temperature inside the cabinet. Optical fiber temperature measurement uses optical fiber as a temperature sensor and modulates the light intensity passing through the optical fiber through temperature changes to determine the temperature. It requires higher equipment such as light source, transmitting and receiving circuits. The red I-N temperature method determines the temperature of the measured target by responding to the change in infrared radiation. This temperature measurement method has low accuracy. Based on this, this article proposes a wireless temperature measurement system for high-voltage switch cabinets based on a single-chip microcomputer. This system has the characteristics of accurate temperature measurement and easy installation.

2 Overall system design

2.1 System design requirements

High-voltage switchgear is an important equipment in the power system. It operates in an environment with strong electromagnetic noise for a long time and has high requirements for reliability and stability. Therefore, for the special operating environment of high-voltage switchgear, the monitoring system should meet the following requirements. (1) It can operate stably for a long time without frequent battery replacement; (2) It can adapt to complex electromagnetic noise environment; (3) It is small and easy to deploy at the contact position; (4) The system requires high reliability.

2.2 Overall system design plan

The wireless temperature measurement system for high-voltage switch cabinets mentioned in this article mainly includes three parts: a wireless temperature measurement module, a towel collector, and a host computer server. The wireless temperature measurement module is installed at the contacts in the high-voltage switch cabinet to detect the contact temperature, and The detected temperature signal is sent to the temperature collector wirelessly. The temperature collector is connected to the host computer server through a wired network, and transmits the temperature of the contacts in the high-voltage switch cabinet to the host computer server in real time. The host computer can realize high-voltage switching. It can display, store, alarm and query historical data of the cabinet temperature data, thereby completing the detection and early warning of the electric shock temperature in the high-voltage switch cabinet.

Figure 1 High-voltage switch cabinet wireless temperature measurement system architecture

For the temperature acquisition module of the lower computer, it mainly consists of a single-chip microcomputer control module, a temperature sensor module, a wireless transceiver module, and a power supply module. Its structure is shown in Figure 2.

Figure 2 Temperature acquisition architecture

3. Acrel temperature online monitoring system solution

3.1 Overview

The electrical contact online temperature measurement device is suitable for temperature monitoring of cable joints, circuit breaker contacts, knife switches, high-voltage cable intermediate ends, dry-type transformers, low-voltage and high-current equipment in high and low voltage switch cabinets to prevent oxidation due to oxidation during operation. , looseness, dust and other factors cause excessive contact resistance and heating, which becomes a safety hazard. Improve equipment safety and security, timely, continuously and accurately reflect the equipment operating status, and reduce equipment accident rates.

The Acrel-2000T wireless temperature measurement and monitoring system communicates directly with the equipment in the bay layer through the RS485 bus or Ethernet. The system design follows the international standard Modbus-RTU, Modbus-TCP and other transmission protocols, and security, reliability and openness are all achieved. greatly improved. The system has remote signaling, telemetry, remote control, remote adjustment, remote setting, event alarm, curve, bar graph, report and user management functions. It can monitor the equipment operation status of the wireless temperature measurement system, achieve rapid alarm response, and prevent serious failures. .

3.2 Application places

It is suitable for temperature monitoring of power equipment in the ubiquitous power Internet of Things, steel plants, chemicals, cement, data centers, hospitals, airports, power plants, coal mines and other factories and mines, and power transformation and distribution stations.

3.3 System structure

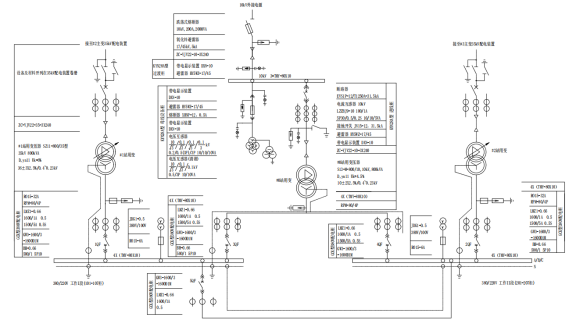

Temperature online monitoring system structure diagram

3.4 System functions

The temperature measurement system host Acrel-2000T is installed in the duty monitoring room and can remotely monitor the operating temperature status of all switching equipment in the system. The system has the following main functions:

3.4.1 Temperature display

Displays the real-time value of each temperature measurement point in the power distribution system, and can also remotely view data via computer WEB/mobile phone APP.

3.4.2 Temperature curve

View the temperature trend curve of each temperature measurement point.

3.4.3 Run the report

Query and print temperature data at each temperature measurement point.

3.4.4 Real-time alarm

The system can issue alarms for abnormal temperatures at each temperature measurement point. The system has a real-time voice alarm function, which can issue voice alarms for all events. The alarm methods include pop-up windows, voice alarms, etc. It can also push alarm messages via SMS/APP to promptly remind the personnel on duty.

3.5 System hardware configuration

The temperature online monitoring system is mainly composed of temperature sensors and temperature acquisition/display units at the equipment layer, edge computing gateways at the communication layer, and temperature measurement system hosts at the station control layer to realize online temperature monitoring of key electrical parts of the power transformation and distribution system.

Name | Picture | Model | Parameter Description |

System configuration software |

| Acrel-2000/T | Hardware: 4G memory, 500G hard disk, Ethernet port. Monitor: 21 inches, resolution 1280*1024. Operating system: Windows 764-bit Simplified Chinese Ultimate Edition. Database system: MicrosoftSQLServer2008R2. Communication protocol: IEC60870-5-103, IEC60870-5-104, ModbusRTU, ModbusTCP and other international standard communication protocols |

Gateway |

| Anet-2E4SM | Universal gateway, 2 network ports, 4 RS485, optional 1 LORA, live alarm function, supports 485, 4G slave module expansion. |

Wireless temperature measurement centralized collection equipment |

| Acrel-2000T/A | Wall mounting Standard configuration: one 485 interface and one Ethernet port Comes with buzzer alarm Cabinet size 480*420*200 (unit mm) |

| Acrel-2000T/B | Hardware: 4G memory, 128G hard disk, Ethernet port Monitor: 12 inches, resolution 800*600 Operating system: Windows7 Database system: MicrosoftSQLServer2008R2 optional Web platform/APP server cabinet size is 480*420*200 (unit mm) | |

Display terminal |

| ATP007 ATP010 | DC24V power supply; one upstream RS485 interface; one downstream RS485 interface; Can receive 1 ATC600-C. |

| ARTM-Pn | Face frame 96*96*17mm, depth 65mm; opening 92*92mm; AC85-265V or DC100-300V power supply; Uplink RS485 interface, Modbus protocol; Can receive 60 ATE100/200/300/400; matched with ATC450. | |

| ASD320 ASD300 | Face frame 237.5*177.5*15.3mm, depth 67mm; opening 220*165mm; AC85-265V or DC100-300V power supply; Uplink RS485 interface, Modbus protocol; Can receive 12 ATE100/200/300/400; | |

Intelligent temperature inspection instrument |

| ARTM-8 | 35MM guide rail installation; AC85-265V or DC100-300V power supply; Uplink RS485 interface, Modbus protocol; 24 channels of NTC or PT100, 1 channel of temperature and humidity measurement, 2 channels of relay alarm output, used for temperature measurement in low-voltage electrical contacts, transformer windings, click windings and other places; |

| ARTM-24 | 35MM guide rail installation; AC85-265V or DC100-300V power supply; Uplink RS485 interface, Modbus protocol; 24 channels of NTC or PT100, 1 channel of temperature and humidity measurement, 2 channels of relay alarm output, used for temperature measurement in low-voltage electrical contacts, transformer windings, click windings and other places; | |

Wireless transceiver |

| ATC450-C | Can receive data from 60 ATE100/ATE100M/ATE200/ATC400 |

| ATC600 | ATC600 is available in two specifications; ATC600-C can receive data from 240 ATE100/ATE100M/ATE200/ATC400/ ATE100P/ATE200P sensors. ATC600-Z relay transparent transmission. | |

Wireless temperature sensor |

| ATE100M | Battery powered, lifespan ≥5 years; -50℃~+125℃; Accuracy ±1℃; 470MHz, open distance 150 meters; 32.4*32.4*16mm (length*width*height). |

| ATE200 | Battery powered, lifespan ≥5 years; -50℃~+125℃; Accuracy ±1℃; 470MHz, open distance 150 meters; 35*35*17mm, L=330mm (length*width*height, three-color strap). | |

| ATE200P | Battery powered, lifespan ≥5 years; -50℃~+125℃; Accuracy ±1℃; 470MHz, open distance 150 meters, protection level IP68; 35*35*17mm, L=330mm (length*width*height, three-color strap). | |

| ATE400 | CT induction power supply, starting current ≥5a; -50℃~125℃; accuracy ±1℃470MHz, open distance 150 meters; The alloy sheet is fixed and powered; three-color shell; 25.82*20.42*12.8mm (length*width*height). |

References:

[1] Acrel Enterprise Microgrid Design and Application Manual. Version 2022.05